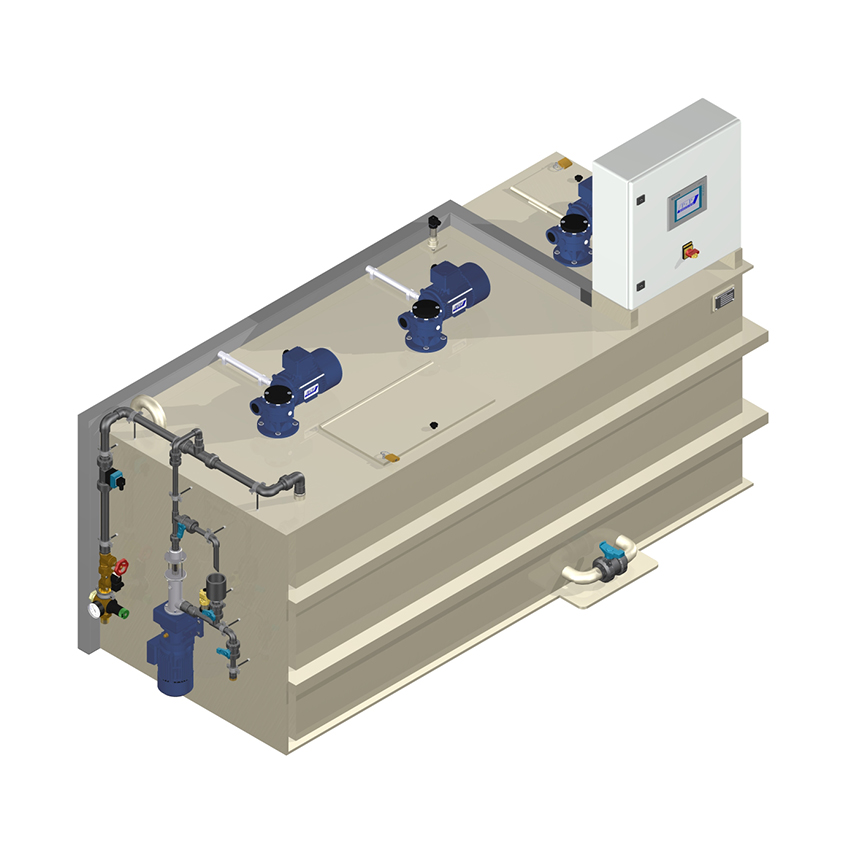

Two-chamber batch system

PCF Series / horizontal design

Make-up unit for liquid polymers

Fully automated control of the make-up process

Extraction of an accurately concentrated solution from one chamber while solution is simultaneously being made up in the second chamber.

Standard units

from PCF 500 to PCF 4000

with 5.0 – 40.0 kg active substance per hour

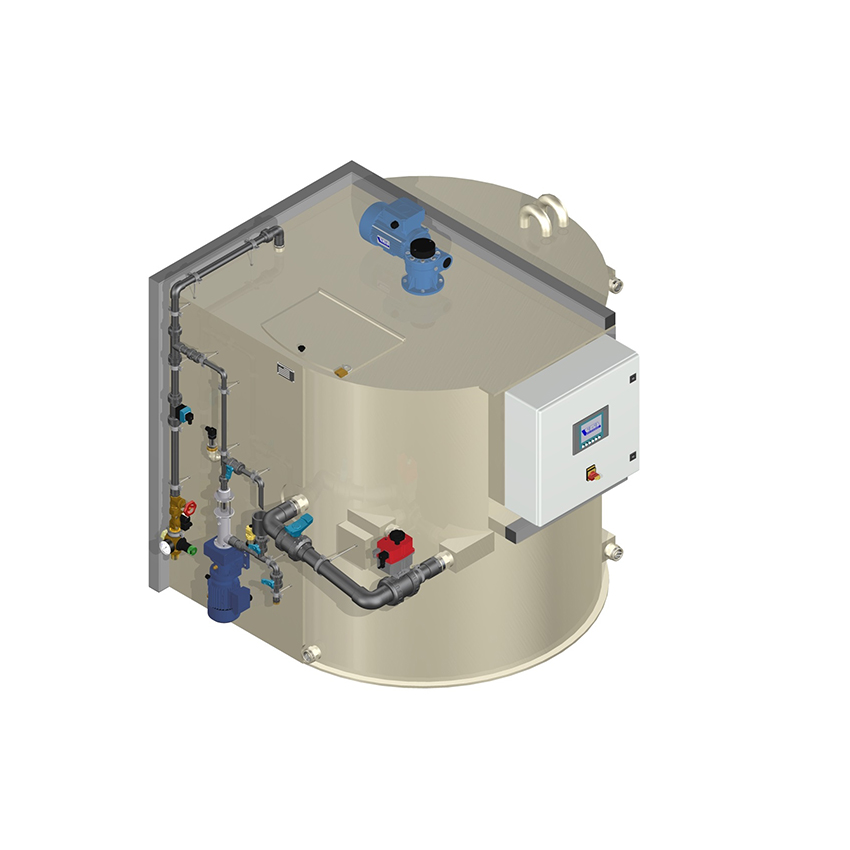

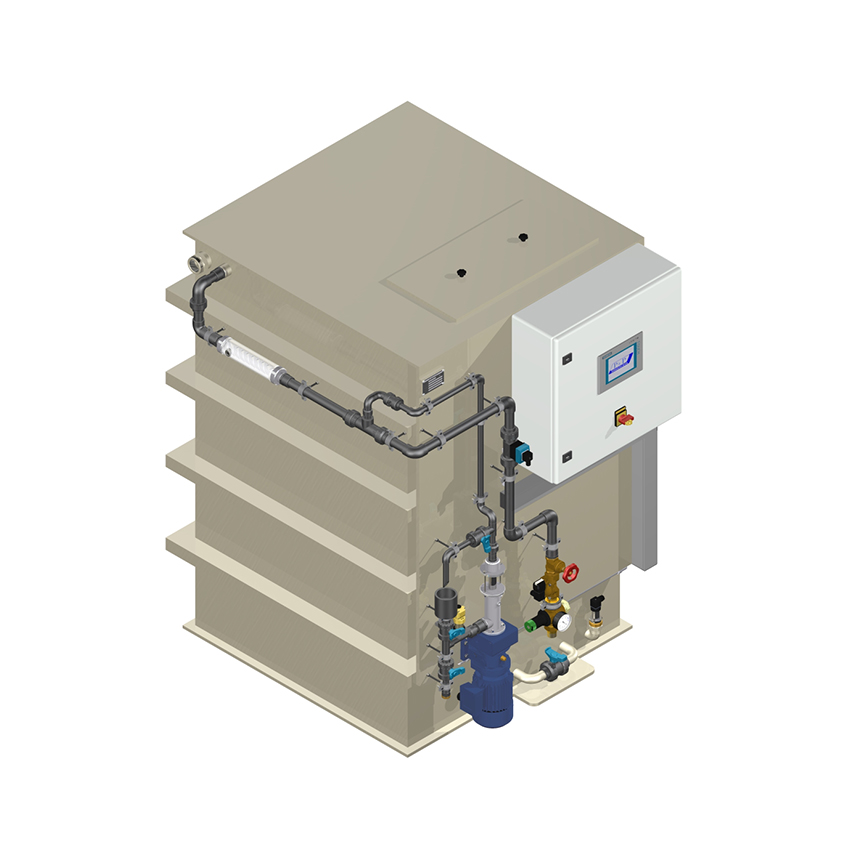

Two-chamber batch system

PCFD-R Series / vertical design

Make-up unit for liquid polymers with fully automated control. With the two chambers being arranged one on top of the other, the on-site space requirements are considerably reduced.

Standard units

from PCFD-R 500 to PCFD-R 2000

with 5.0 – 20.0 kg active substance per hour

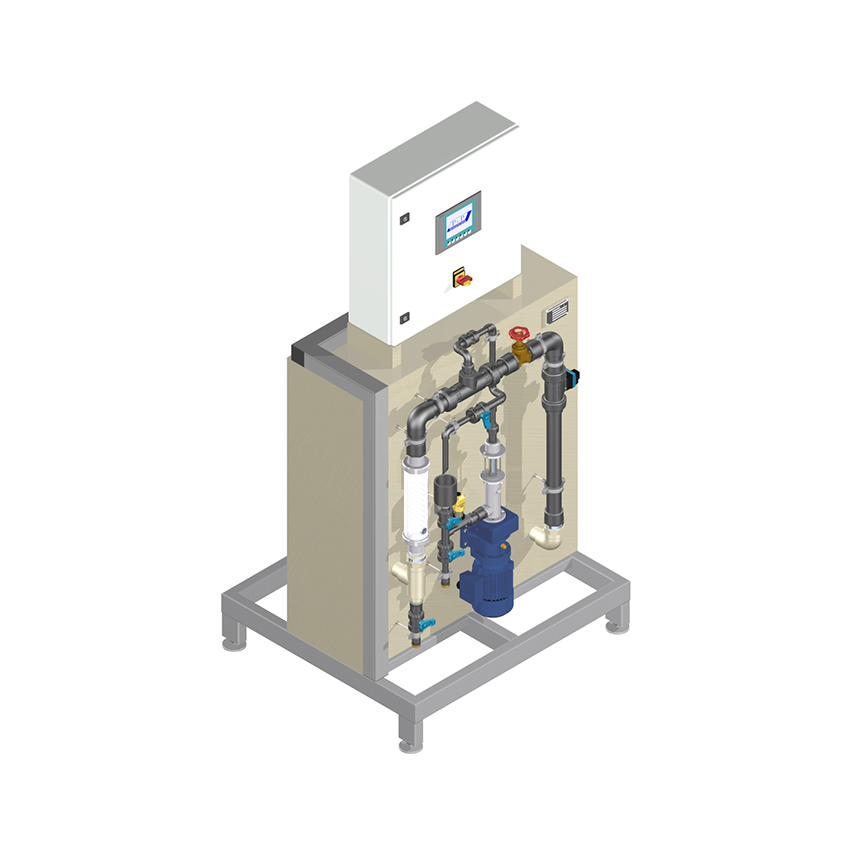

Inline unit for liquid polymers

PolyMix Series

Inline unit for liquid polymers with highly accurate product preparation and immediate dosage without the need of adhering to any maturing times. This unit does not require a separate tank.

Standard units

from PolyMix 2000 to PolyMix 20000

with 2 – 200 kg active substance per hour